So this isn't a recap of my study abroad last semester (that's coming, trust me), but instead a recap of a much more recent adventure: Winter Term 2015!

Students need to complete three full Winter Term projects in order to graduate, and for my third and final Winter Term I wanted to do something different from my previous projects. For my freshman year I interned at the Carnegie Museum of Natural History in Pittsburgh and spent the month working with the volunteer programs in the community outreach department, and for my sophomore year I stayed on campus and took the Practicum in Museum Education course at the Allen Memorial Art Museum. Both were great experiences, but were a lot of work and not much of a break from regular schoolwork. After a semester of traveling and anticipating the incoming jet lag, I wanted my final Winter Term to give me time to readjust to being on campus again yet still teach me something new.

Enter alum Aimee Lee and the Papermaking Winter Term. After managing to apply online despite the 6-hour time difference between me and campus at the time, I was accepted into Aimee's eight-person class to learn Asian and Western styles of papermaking and bookbinding.

All images (c) Ed Vermue and Aimee Lee

I was really excited for the class--visual arts classes were my favorite in high school, and I hadn't had the chance to take any in my three years at Oberlin so far. The opportunity to work with my hands for five hours a day, five days a week was very appealing after so many semesters of heavy reading and essay-writing! Aimee Lee herself proved to be a very engaging teacher and a fascinating artist to work with; she told us about her travels in Korea and Japan to learn traditional papermaking techniques and collaborate with artists. During the course of the class she took us on a fieldtrip to the Morgan Conservatory and Zygote Press print shop in Cleveland to show us professional papermaking, bookbinding, and letterpress facilities she's worked with.

.JPG)

Aimee Lee demonstrating an electric beater at the Morgan Conservatory

Aimee showing us different fiber samples

Dying paper at the Morgan Conservatory (yes, it was very cold inside!)

So if you're wondering how making paper can take five hours or more each day, here's a rough summary of how traditional Asian paper is made:

- Kozo (Japanese mulberry) is grown and harvested.

- The outer black bark and inner green bark is stripped away from the stalk, leaving the inner white bark. This is the fiber used to make traditional white paper.

- This white bark is then boiled with soda ash to begin softening it into pulp.

- After rinsing the soda ash out of the fiber, the kozo is gathered into dough-like portion and beat into pulp using wooden bats. Depending on the desired fineness of the paper, the beating can take anywhere from one to five hours! Because of the constraints of class time and our own physical weaknesses, we typically beat the kozo for only half an hour.

- The pulp is submersed in a vat of water with a dispersal solution that makes the fiber spread more evenly in the water to achieve more even sheets.

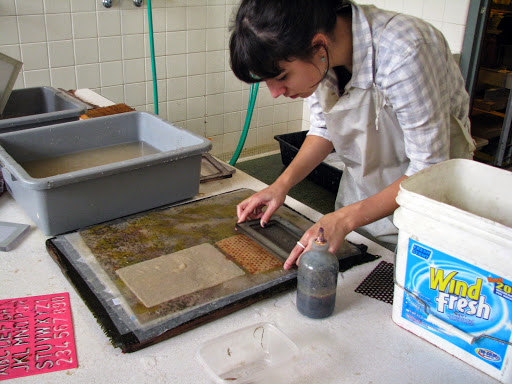

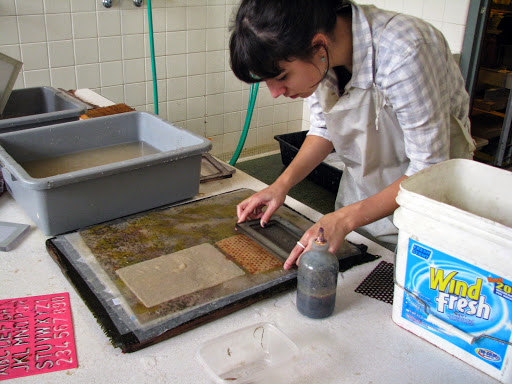

- Now comes the actual papermaking: pulling each sheet from the vat and dipping multiple times for desired thickness, then transferring the sheet to wet board to await pressing. Repeat ad infinitum, or until you've used as much fiber as possible.

- Once all students were done pulling sheets for the day, we loaded the wet boards into a hydraulic press.

- After unloading the press, the sheets are transferred by hand to a drying box, and left to dry overnight. The pressing the drying process is repeated for however many sheets didn't fit into the last drying box run.

Scraping kozo stalks

Beating the pulp

.JPG)

Our wet studio in Hales

Pulling and couching sheets

Transferring sheets from the press to the drying box

The class was organized with one week devoted to Asian papermaking, one week devoted to Western papermaking, and the final week devoted to bookbinding. We also spent one day trading places with Ed Vermue's Letterpress Studio Winter Term class in the library, and taught them to make paper while we learned marbling.

Ed Vermue supervising a marbling lesson in the letterpress studio in Mudd Library

Decorated papers hanging to dry in the Hales studio

Papers marbled in Japanese sumi ink style

The Letterpress Studio class and the Papermaking class working together!

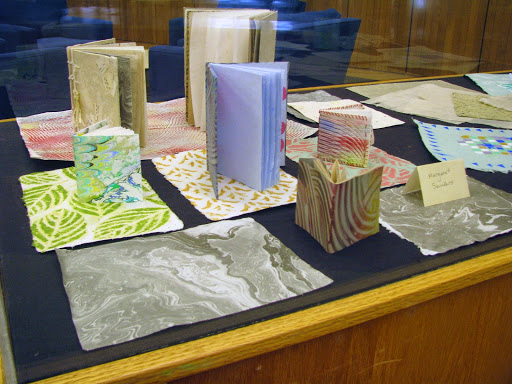

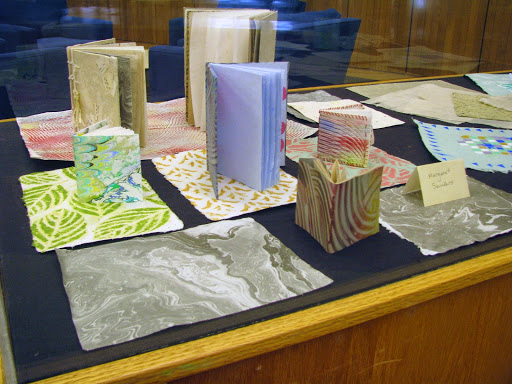

I'd have to say that out of all three weeks, my favorite was the bookbinding week. It was so much fun to gather everything I'd made--over 150 sheets of paper in total--and combine it to create something else. Often I'd find myself "zoned out" while working, I was so engrossed! On the final day of class, we chose our favorite pieces to put in a small show in the display cases on the first floor of Mudd Library, and I definitely encourage you to come and check them out.

Students working on bookbinding in Mudd Library Special Collections

Setting up my display case

My works!

I have to name this final Winter Term as my definite favorite. It felt great to create art again, and to create art with the talented people in my class and learn from Aimee and Ed. It couldn't have been a better way to start 2015!

Class of 2015

Links: